Preserving Montgomery County: A Unified Effort from US Aggregates®, Evergreen Roadworks™ and Asphalt Materials, Inc.

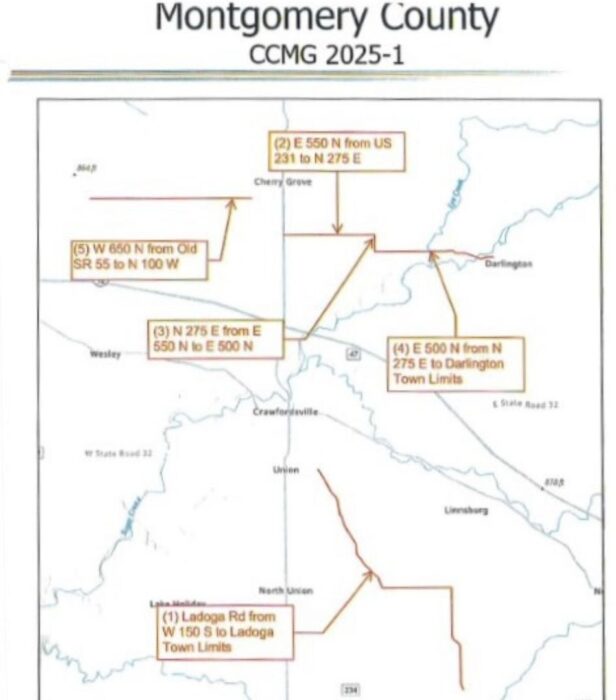

In Montgomery County, Indiana, three Heritage Construction + Materials companies — US Aggregates®, Evergreen Roadworks™ and Asphalt Materials, Inc. — came together to deliver a cape seal application across more than 21 miles of roadway. This collaborative effort was made possible through the Community Crossings Matching Grant Program, a state initiative administered by the Indiana Department of Transportation (INDOT), that supports local governments in preserving and maintaining critical infrastructure.

The project applied 280,687 square yards of AMISEAL™ cape seal across several key routes in Montgomery County. Each segment was selected based on traffic volume, PASER (Pavement Surface Evaluation and Rating) measurements and prior crack sealing work. While the roads were still in relatively good condition, they were beginning to show signs of surface distress. Cape seal, a combination of chip seal and micro surfacing, was chosen for this project because of its durability and improved surface quality.

The project began with US Aggregates, whose Delphi and Ridgeville plants produced a high-quality stone product known for its hardness and low emulsion absorption. This stone was staged at the Crawfordsville location, strategically located near Evergreen Roadworks’ field operations. US Aggregates Plant Manager Brian Morrison and Front Load Operator Randy Myers coordinated with the Delphi and Ridgeville teams on trucking schedules and ensured the staging area was ready for multiple daily pickups. Their efforts helped streamline the flow of materials to the field site, keeping production on pace. Randy, who has worked for US Aggregates for 15 years, has moved more than 2.5 million tons of earth over his career, a powerful testament to the experience and dedication behind the scenes.

Evergreen Roadworks deployed two specialized crews for the cape seal process: one for chip seal and another for micro surfacing. These crews travel across the Midwest, applying pavement preservation treatments with precision and speed. In Crawfordsville, the team completed the application in just six days, with both crews working long hours to ensure the roads were sealed and surfaced efficiently. Safety remained a top priority with traffic control personnel managing lane changes and vehicle flow in tight quarters. The team’s cohesion and rhythm were evident, supported by management who kept morale high and hydration flowing during hot summer days.

The chip seal process began with a polymer modified asphalt-emulsion, AE-90S, sprayed onto a swept road surface, followed closely by the aggregate spreader operated by Joey Hannah, a skilled team member with nearly two decades of experience. Carefully executed in the presence of construction traffic, compaction was achieved using two pneumatic tire rollers under the supervision of foreman Wyatt.

The next stage of the project was micro surfacing, which took place two weeks later. This crew applied a thin asphalt overlay that sealed the surface, restored uniform texture and enhanced skid resistance creating a smooth, durable finish that will extend the life of the roadway for years. The micro surfacing phase was led by foreman Chase, with Darrin actively training to step into a lead role. Their team of around 16 brought precision and efficiency to this final step in the cape seal process.

Among the crew was Ron Williams, a CDL-certified driver who operates the company’s 42-wheel emulsion tanker. A lifelong trucker, Ron values Evergreen Roadworks’ commitment to its people. Another familiar face is Front Loader Operator Ruhl Norris, who has been with Evergreen for over a decade and has moved more than 1.2 million tons of earth. His pride in the company stems from the respect and appreciation he receives on the job.

Asphalt Materials, Inc. (AMI) supplied the essential emulsion products that made the cape seal possible. For the chip seal portion, a polymer-modified emulsion was produced at AMI’s Indianapolis plant. The micro surfacing latex–modified emulsion came from the Oregon plant. At the field site, emulsion was staged alongside water and aggregate. Evergreen’s 18-wheelers cycled through to load and transport materials to the construction site where they were offloaded into the micro surfacing applicator and applied directly to the roadways.

AMI’s partnership with Montgomery County Highway Department has grown over the years, built on shared values and a mutual understanding of pavement preservation. Sales Representative Nate Jenkins described the county as a standout partner, one that recognizes the importance of choosing the right treatment at the right time. County Highway Superintendent Jake Lough has been instrumental in this progress. A certified Roadvocate through the PPRA Road Resource Network Bootcamp, Jake has led the county’s efforts with a focus on proactive planning and asset management.

“Pavement preservation is like replacing the roof on a home,” Jake explained. “It protects the structure and avoids costly reconstruction.” He’s seen firsthand how neglecting regular maintenance accelerates deterioration and drives up costs. The success of this cape seal project means these roads won’t require additional maintenance for eight to ten years, allowing taxpayer dollars to be redirected to other parts of the network.

At AMI’s Indianapolis plant, Assistant Plant Manager Dan Robinson, along with the dedicated team at the Indianapolis Plant, helped ensure the emulsion was produced to the highest standards. With more than 40 years at the company, Dan’s roots run deep. His father worked at AMI, and he began spending summers at the plant in high school. Today, his son Zach continues the legacy at Heritage Research Group. Known for his patient leadership and technical expertise, Dan has become a mentor and problem-solver, helping the team deliver safe, efficient operations every day.

Together, US Aggregates, Evergreen Roadworks and Asphalt Materials, Inc. demonstrated what it means to live the values of Heritage Construction + Materials. Through long-term relationships, mutual trust and a commitment to doing the right thing, they delivered a high-quality, cost-effective solution that will serve Montgomery County’s residents for years to come.

About Heritage Construction + Materials

Heritage Construction + Materials (HC+M) is part of The Heritage Group, a privately held, family-owned business headquartered in Indianapolis. HC+M has core capabilities in infrastructure building. Its collection of companies provides innovative road construction and materials services across the Midwest. HC+M companies, including Asphalt Materials, Inc., Evergreen Roadworks, Milestone Contractors and US Aggregates, proudly employ 3,000 people at 85 locations across seven states. Learn more at www.heritagebuilds.com.

About Asphalt Materials, Inc.Asphalt Materials is a privately held, family-owned business headquartered in Indianapolis. Over its 66-year history, Asphalt Materials has prioritized safety and created a people-focused culture around asphalt expertise and innovation. Through its commitment to building long-term relationships with employees, customers, and vendors based on trust and confidence, Asphalt Materials creates solutions to issues affecting customers and our communities. Asphalt Materials is a part of The Heritage Group’s family of businesses. Learn more at www.asphalt-materials.com.

About Evergreen RoadworksEvergreen Roadworks provides a wide-ranging suite of pavement solutions and applications. For generations, we have partnered with state and local agencies across the Midwest offering products and services that extend roadway life and increase infrastructure longevity. We work to stretch our customers’ investments, building high-quality, long-lasting roadways that truly connect our communities in a better way. Evergreen’s commitment to excellence in paving and pavement preservation goes beyond roadwork – to building relationships and crafting the foundations of our communities.

About US AggregatesUS Aggregates is a privately held, family-owned business headquartered in Indianapolis. With over 20 operations across Indiana, US Aggregates has been a customer-focused, innovative provider of high-quality essential stone, sand and gravel used in road construction, site prep and utilities, agriculture and erosion control. The company also specializes in industrial minerals like dolomitic and high-calcium products. Since 1967, US Aggregates has built a reputation for prioritizing safety, quality and community. US Aggregates is a part of The Heritage Group’s family of companies. Learn more at www.usagg.com.